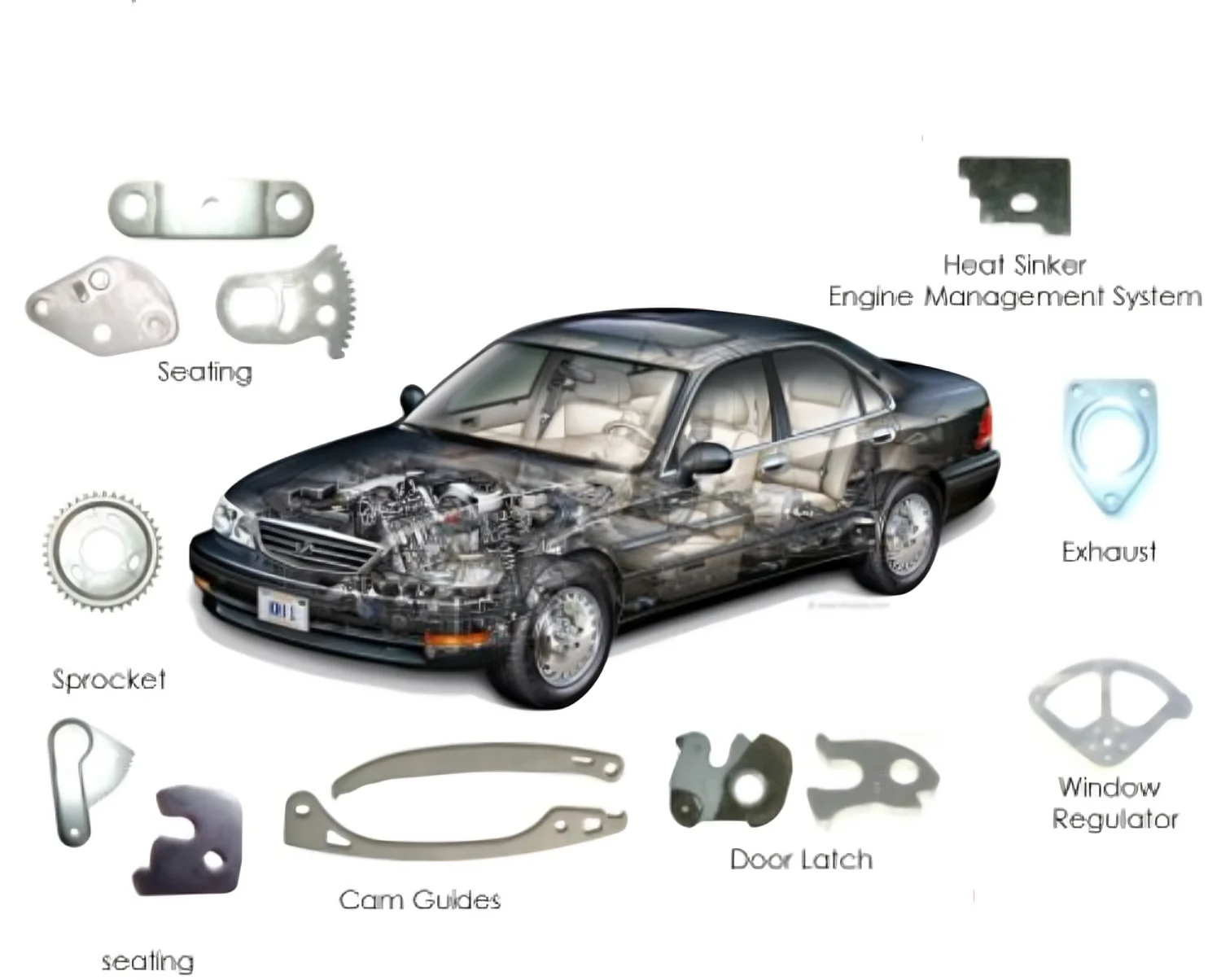

Fineblanked automotive components represent the pinnacle of precision engineering, embodying the synergy between cutting-edge technology and automotive excellence. Engineered with meticulous attention to detail, these components offer unparalleled dimensional accuracy and consistency, essential for the demanding requirements of modern vehicles. Whether it's intricate transmission gears, complex clutch plates, or critical brake system parts, fineblanking technology ensures that each component meets the exacting standards of the automotive industry, guaranteeing optimal performance and reliability on the road.

Within Blanking & Forming, the utilization of fineblanking technology stands as a cornerstone in our commitment to excellence in the automotive industry. With precision at the forefront of our operations, fineblanking ensures the production of intricate metal components with unmatched accuracy and consistency, aligning perfectly with our company's ethos of delivering top-tier quality.

By leveraging the advantages of fineblanking, such as tight tolerances and superior surface finish, we streamline production processes, optimize costs, and uphold the highest standards of performance and safety in the automotive parts we manufacture. Through our dedication to fineblanking, Blanking & Forming continues to play a pivotal role in shaping the future of automotive engineering, providing clients with components that exceed expectations in both quality and reliability.

Secondary finishing processes play a crucial role in refining automotive components to meet the stringent quality standards and aesthetic requirements of the industry. After the primary manufacturing processes like casting, forging, or fineblanking, secondary finishing steps are employed to enhance the functionality, durability, and visual appeal of the parts. These processes may include machining, grinding, polishing, heat treatment, and coating. Machining ensures precise dimensional accuracy, while grinding removes surface imperfections and improves the part's surface finish. Polishing adds a smooth, lustrous surface, enhancing both aesthetics and functionality.

The precision and repeatability offered by fineblanking make it the perfect process for manufacturing critical automotive components, especially for ultra-high volume production. Fineblanked parts exhibit exceptional accuracy and consistency, meeting the stringent requirements of the automotive industry.

In addition to traditional internal combustion engine (ICE) vehicles, fineblanking is well-suited for producing components for electric drive systems used in Hybrid Electric Vehicles (HEV), Battery Electric Vehicles (BEV), and Fuel Cell Electric Vehicles (FCEV). This versatility allows for the production of various electric powertrain components, including electric motors, transmissions, engine management systems, turbochargers, and fuel systems.

Fineblanking's capability to stamp large parts and thick materials in high-tonnage presses positions it as the ideal process for manufacturing heavy-duty components across various industries.

In the realm of heavy-duty applications, fineblanking proves invaluable in the production of diesel engine components, where precision and durability are paramount. Additionally, it excels in manufacturing powertrain components, encompassing transmissions, engine management systems, fuel systems, and turbochargers. The ability to maintain tight tolerances and produce intricate geometries ensures optimal performance in demanding powertrain applications.

Fineblanking stands out for its ability to produce net shape and near net shape components, reducing or even eliminating the need for extensive machining processes. This capability is particularly advantageous when working with materials like stainless steel, aluminum, and exotic alloys, where precision and surface finish are crucial.

In the medical industry, fineblanking finds numerous applications in the manufacturing of diagnostic equipment, endoscopy equipment, orthopedic devices, and surgical instruments components.

The integration of fineblanking with precision manufacturing techniques and the use of super alloy materials enables the creation of components with exceptional strength, durability, and mechanical reliability. This combination is particularly advantageous in industries such as commercial aviation, space exploration, and military applications, where reliability under extreme conditions is paramount.

Fineblanking is renowned for its ability to consistently produce strong, high-quality components, making it an essential process in the manufacturing of military and defense products. These components play a critical role in various military operations, whether in combat theaters, supporting humanitarian efforts, or peacekeeping missions. In the military and defense sector, fineblanking finds applications in the production of components for a wide range of equipment, including mechanical firearms, combat knives, service utility tools, and ammunition.