At Blanking and Forming, we take pride in our unparalleled expertise in press tool design and manufacturing. With a robust capacity that surpasses our competitors, we've carved a niche for ourselves, fostering high customer satisfaction and reliability.

With a repertoire boasting over 1500 types of stampings and laminations, our reach extends across various industry segments. We specialize in crafting critical components for OEMs, with a focus on electrical stampings, die-cast rotors, as well as welded, cleated, and riveted stators.

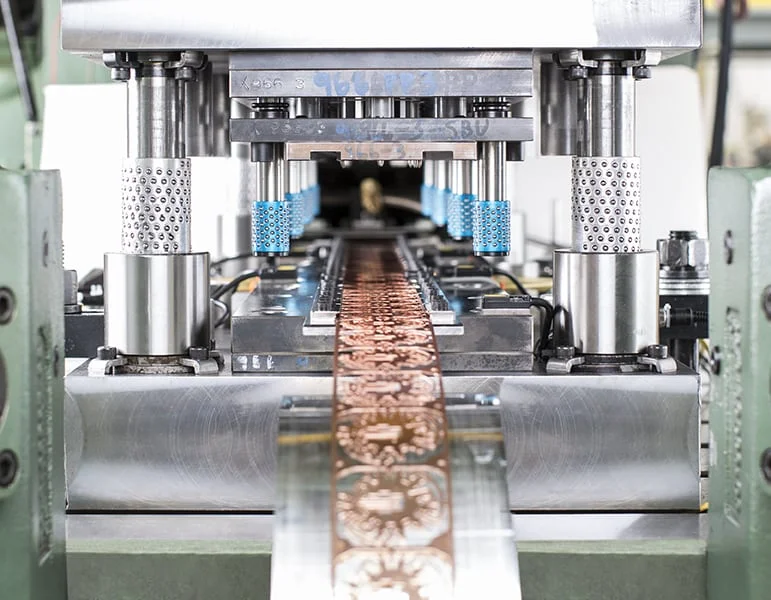

In our power press department, we specialize in conventional stamping and forming processes. Depending on the quantity required, we utilize either automated feed systems or manual placement of parts. Our capacity in this area ranges from 9 to 450 tons, allowing us to work with a wide variety of raw materials including carbon steel, stainless steel, brass, copper, aluminum, elgiloy, inconel, hastelloy, and more.

Similar to our fourslide capabilities, our tool room is equipped to design and build specific tooling tailored to your needs. Our goal is to design tools that can accomplish as much forming as possible directly in the die, thereby reducing or even eliminating the need for secondary operations, which can add unnecessary costs.

Whether it's optimizing production workflows, implementing advanced quality control measures, or exploring novel materials for stamping applications, we are always looking for ways to push the boundaries of what is possible in fine stamping.

In our power press department, we specialize in conventional stamping and forming processes. Depending on the quantity required, we utilize either automated feed systems or manual placement of parts. Our capacity in this area ranges from 9 to 450 tons, allowing us to work with a wide variety of raw materials including carbon steel, stainless steel, brass, copper, aluminum, elgiloy, inconel, hastelloy, and more.

Similar to our fourslide capabilities, our tool room is equipped to design and build specific tooling tailored to your needs. Our goal is to design tools that can accomplish as much forming as possible directly in the die, thereby reducing or even eliminating the need for secondary operations, which can add unnecessary costs.

Whether it's optimizing production workflows, implementing advanced quality control measures, or exploring novel materials for stamping applications, we are always looking for ways to push the boundaries of what is possible in fine stamping.